Effect of processing conditions on quality of green beans subjected to reciprocating agitation thermal processing

Fig. 3. Effect of reciprocation frequency on visual quality of canned green beans processed with 2% CMC at 130 °C Article from Food Research International 78:424-432 AnikaSinghAnubhav, PratapSinghHosahalli, S.Ramaswamy

Effect of can orientation on heat transfer coefficients associated with liquid particulate mixtures during reciprocation agitation thermal processing

Figure 1: Schematic of the three possible orientations inside the reciprocating cage showing the placement of experimental can with its longer axis: a horizontally along the reciprocation axis (HA), b horizontally perpendicular to reciprocation axis (HP), and c vertical (V) Article from Food and Bioprocess Technology 8:1405-1418 Anubhav Pratap Singh, Hosahalli S Ramaswamy

Computational techniques used in heat transfer studies on canned liquidparticulate mixtures

Article from Trends in Food Science & Technology 43:83-103 AnikaSingh, Anubhav PratapSingh, Hosahalli, S.Ramaswamy

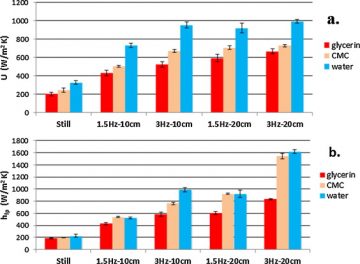

A refined methodology for evaluation of heat transfer coefficients in canned particulate fluids under rapid heating conditions

Fig. 5. Effect of reciprocating conditions on heat transfer coefficients in reciprocation agitation thermal processing: (a) overall heat transfer coefficient (U); (b) fluid-to-particle heat transfer coefficient (hfp). Article from Food and Bioproducts Processing 94:169-179 AnikaSingh, Anubhav PratapSingh, Hosahalli S.Ramaswamy

Modification of a static steam retort for evaluating heat transfer under reciprocation agitation thermal processing

Article from Journal of Food Engineering 153:63-72